Blog Layout

A Case for the Necessity of Proactive Maintenance in Critical Facilities

rleonard85 • Jan 22, 2022

Panoptic Solutions LLC

“Intelligence, Ability, Diligence”

951 7th Street, Stu G., Rochelle IL 61068

www.panoptic-solutions.com

A Case for the Necessity of Proactive Maintenance in Critical Facilities

What is Proactive Maintenance?

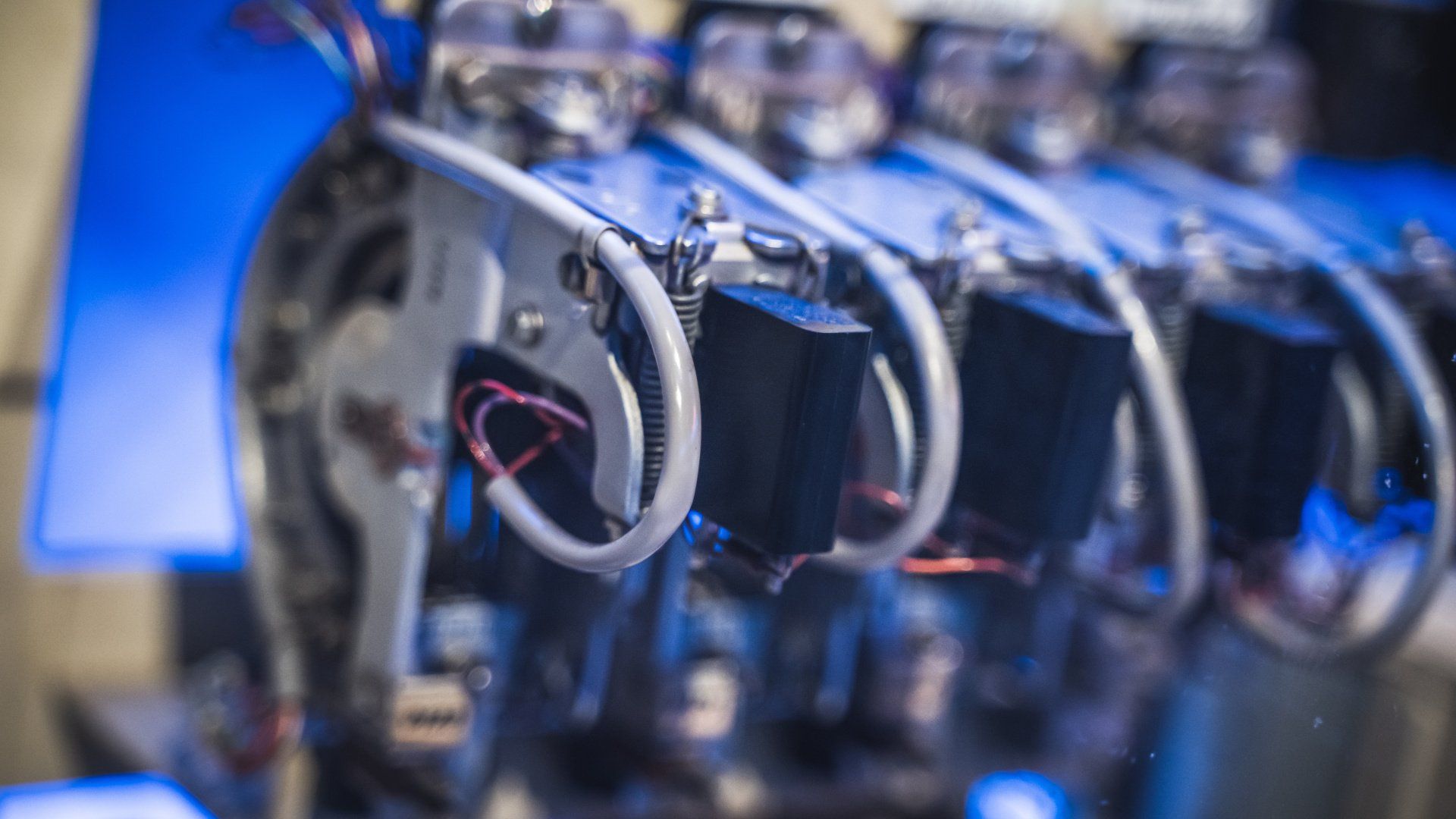

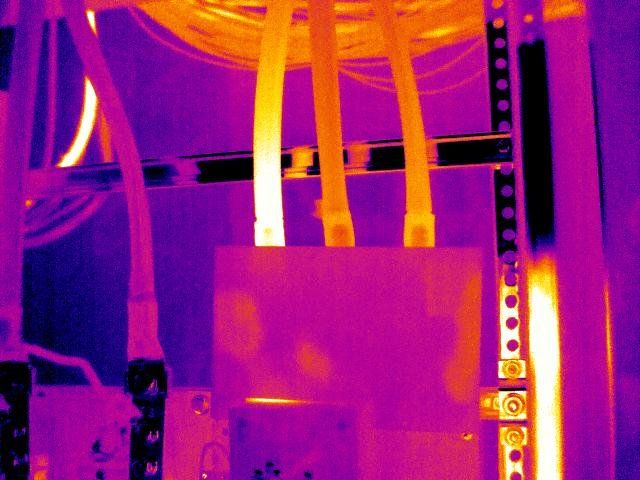

Proactive Maintenance is the process of perpetually and actively testing equipment for signs of impending failure. It involves not only testing but also the collection and review of large amounts of data on all possible pieces of equipment in order to develop a comprehensive picture of what average, healthy equipment looks like. This process allows for the identification of equipment that is performing outside of norms well before that equipment reaches a failure threshold and is in danger of spontaneous failure.

Why is Proactive Maintenance Important? Proactive Maintenance plans are standard operating procedure in military systems because they limit the occurrence of unplanned failures. It goes without saying that unplanned failures represent an unacceptable risk to individual operations as well as entire campaigns. For this reason, successful militaries always employ a proactive maintenance plan on all their field equipment at a minimum.

The famous example of the death of Richard III of England at the Battle of Bosworth Field in 1485 underlines this point perfectly. (Tradition maintains that his horse was stuck in the mud, not that he was without a horse, but the aphorism is often credited to this event all the same.); “For want of a nail, the shoe was lost. For want of a shoe, the horse was lost. For want of a horse, the knight was lost. For want of a knight, the castle was lost.” This led Shakespeare to write the famous line “A horse, a horse, my kingdom for a horse.”

• By identifying small issues before they cascade into systemic failures, operating costs/liability can be significantly reduced • By rating the severity of issues detected, maintenance/repairs can be planned and performed around customer needs to minimize impact of defective/failing equipment • With proper proactive maintenance, issues in equipment installation or manufacture can be identified and resolved at the cost of the installer or manufacturer not the end owner/user

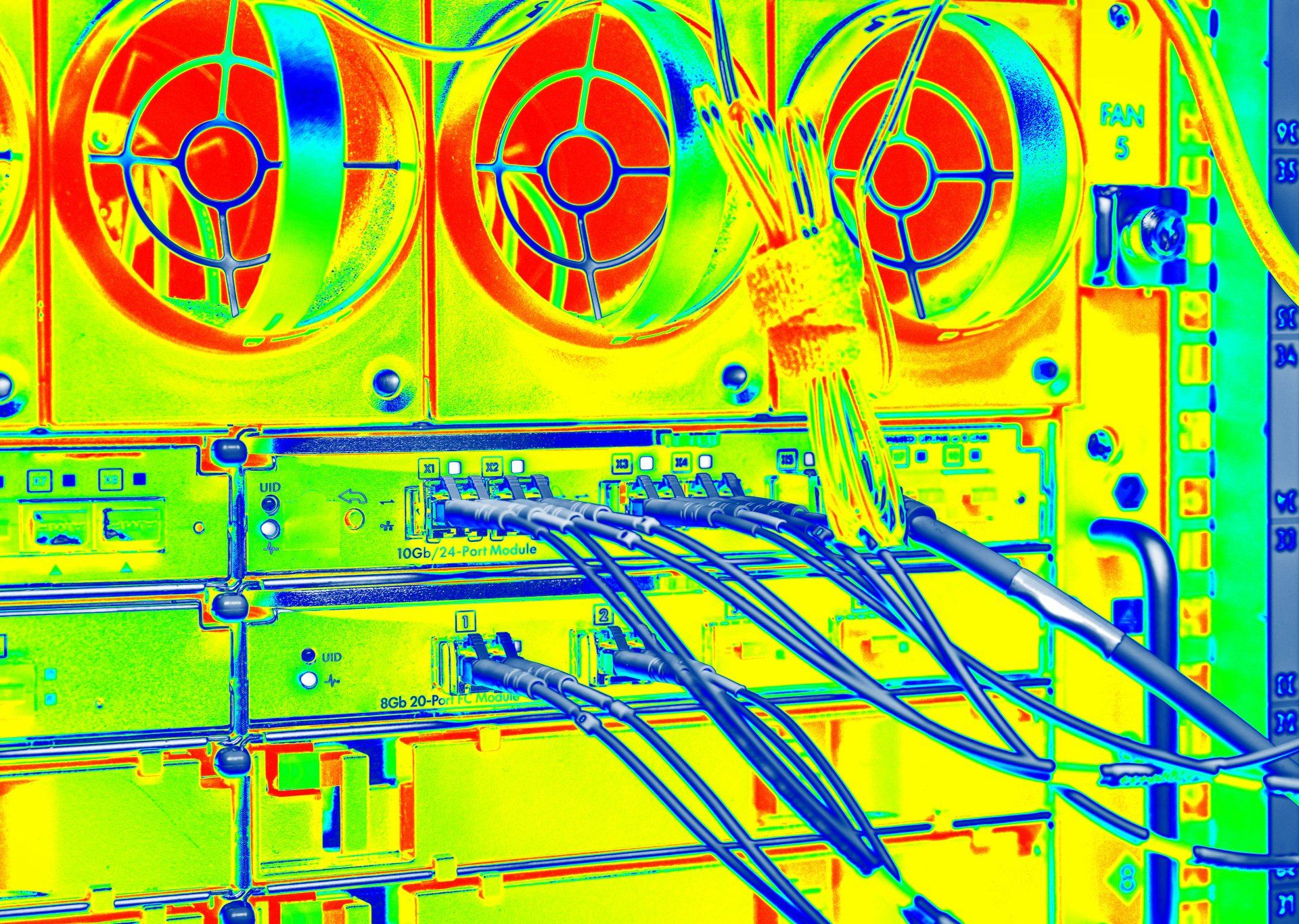

Who Needs a Proactive Maintenance Plan? Any facility or group for whom unplanned service interruptions are not acceptable in normal operations or are operated on the basis of “redundant design” preventing unplanned downtime.

• Data Centers • Hospital Operating Theatres/Imaging Equipment • High throughput manufacturing/refining processes • Telecom sites of all type • Power Plants

Why is Proactive Maintenance Important? Proactive Maintenance plans are standard operating procedure in military systems because they limit the occurrence of unplanned failures. It goes without saying that unplanned failures represent an unacceptable risk to individual operations as well as entire campaigns. For this reason, successful militaries always employ a proactive maintenance plan on all their field equipment at a minimum.

The famous example of the death of Richard III of England at the Battle of Bosworth Field in 1485 underlines this point perfectly. (Tradition maintains that his horse was stuck in the mud, not that he was without a horse, but the aphorism is often credited to this event all the same.); “For want of a nail, the shoe was lost. For want of a shoe, the horse was lost. For want of a horse, the knight was lost. For want of a knight, the castle was lost.” This led Shakespeare to write the famous line “A horse, a horse, my kingdom for a horse.”

• By identifying small issues before they cascade into systemic failures, operating costs/liability can be significantly reduced • By rating the severity of issues detected, maintenance/repairs can be planned and performed around customer needs to minimize impact of defective/failing equipment • With proper proactive maintenance, issues in equipment installation or manufacture can be identified and resolved at the cost of the installer or manufacturer not the end owner/user

Who Needs a Proactive Maintenance Plan? Any facility or group for whom unplanned service interruptions are not acceptable in normal operations or are operated on the basis of “redundant design” preventing unplanned downtime.

• Data Centers • Hospital Operating Theatres/Imaging Equipment • High throughput manufacturing/refining processes • Telecom sites of all type • Power Plants

--Michael Carr

Founding Member of Panoptic Solutions LLC

Formerly a Naval Nuclear Power Plant Operator, and

Project Manager for Nuclear Power Plant repairs

More Posts

Optimize your maintenance cycles

Save Money - Avoid Downtime