Blog Layout

Watchlist Exception Report

rleonard85 • Jan 22, 2022

Watch List Exception Report

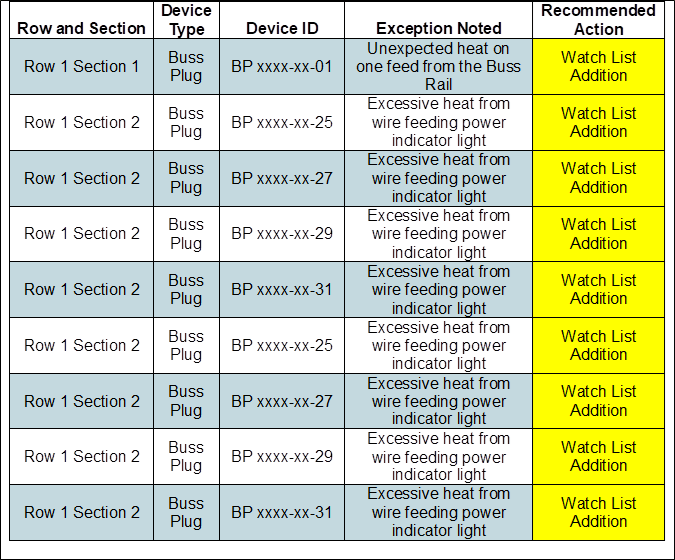

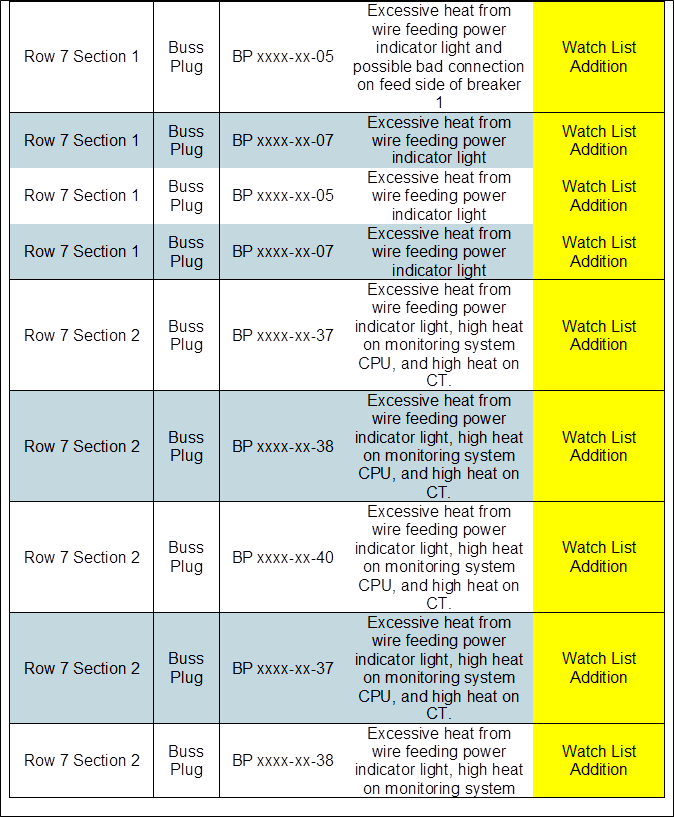

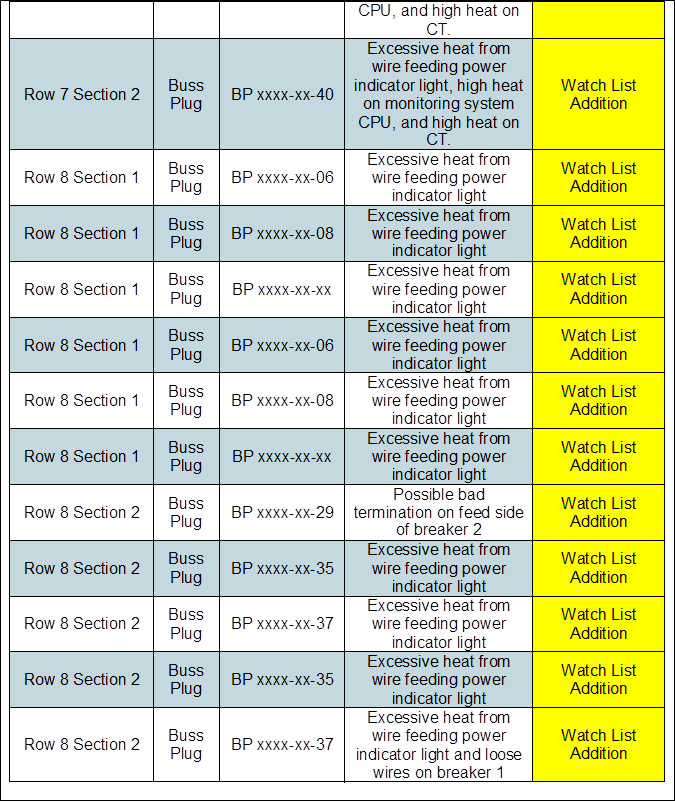

During the Q1 2015 maintenance in room 12 several devices had exceptions noted in their thermal images. The following table lists each device, the exception noted and the recommendation to resolve or track the issue:

Room 12 Watch List Devices

Watch List Devices Discussion

The watch lists above highlight three main exceptions:

1. Buss Plugs with 50 amp breakers – Three distinct issues were noted on these Buss Plugs:

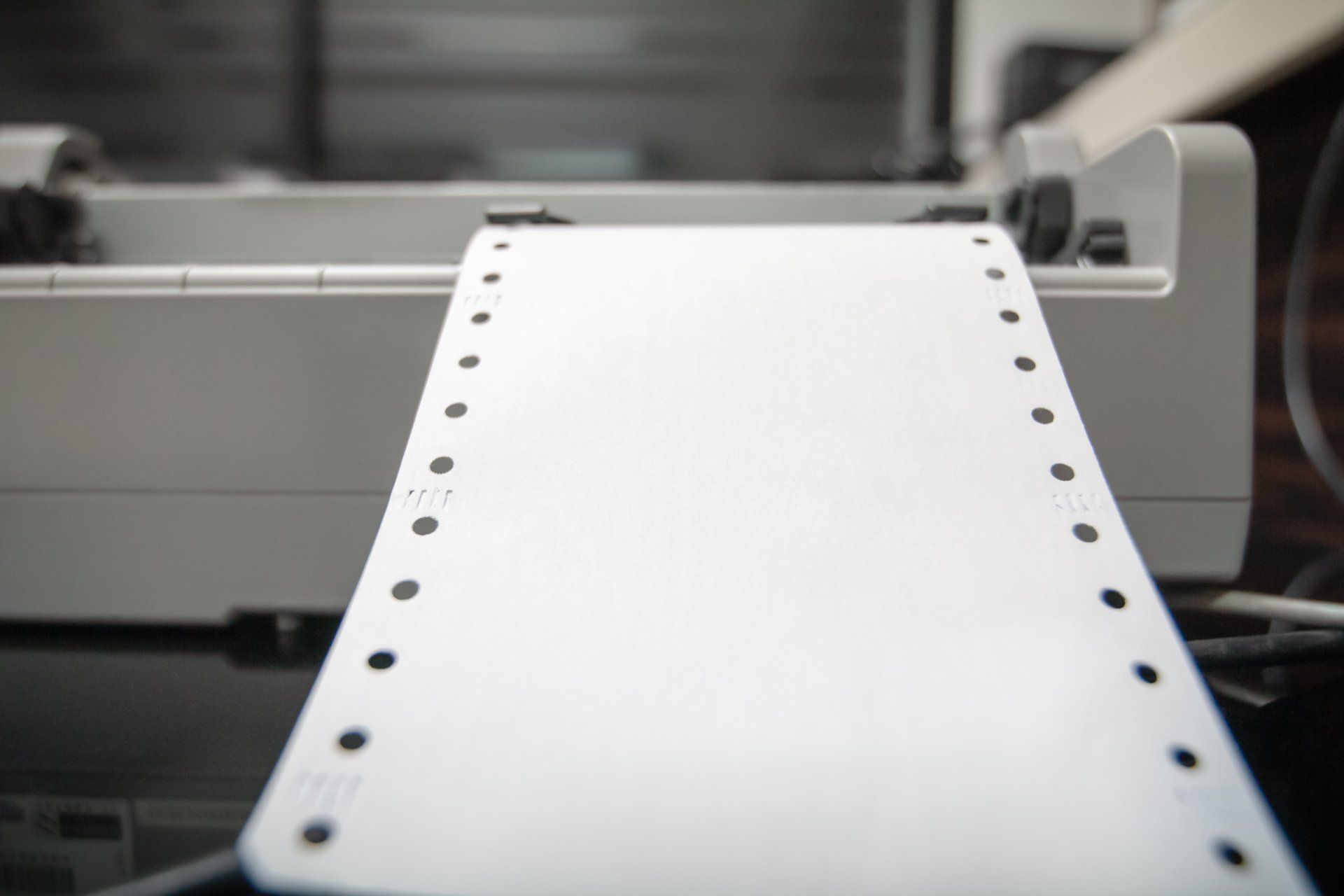

a) Excessive heat coming from a wire feeding a power indicator light occurred on 28 devices. These lights are only used on the Buss Plugs with 3 phase 50 amp circuits. Every Buss Plug of this type showed this exception. Many of these wires are in excess of 90 degrees C (200 degrees F) which is above the rating for the insulation on the wire. The heat on this wire has the potential to cause the insulation to fail and leave a bare wire inside the Buss Plug creating a safety and potential down time hazard. If the indicator light is not needed, it is recommended that the power wire to the light be cut and capped during the next available maintenance period.

b) High heat on the monitoring system board CPU. Over the past year Panoptic Solutions has inspected more than 2,000 Buss Plugs and their accompanying monitoring systems. The temperatures recorded on the monitoring board CPU universally fall between 48 and 57 degrees C (120 and 135 degrees F.) In six Buss Plugs an abnormally high heat was recorded, some in excess of 64 degrees C (147 degrees F.)

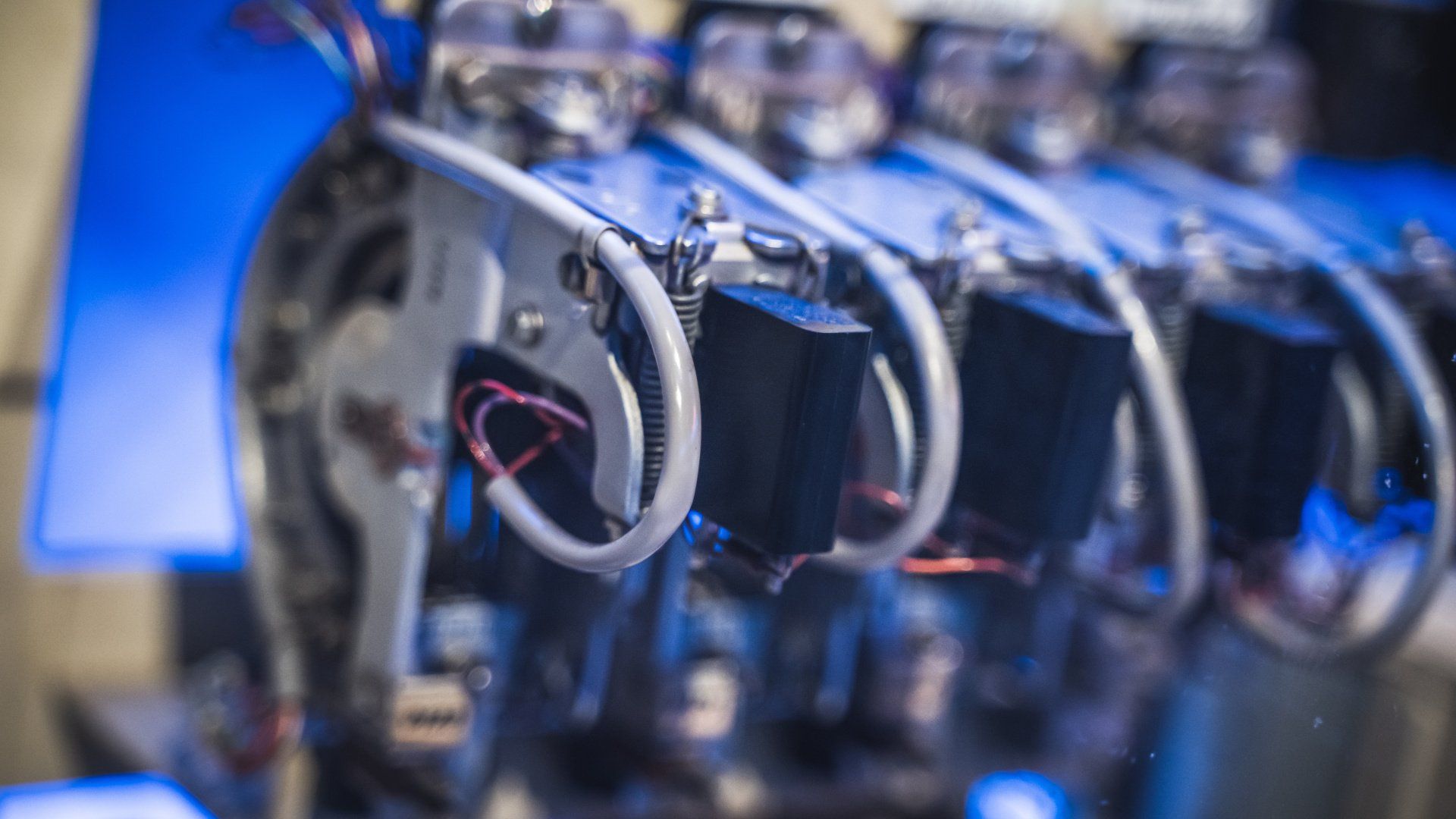

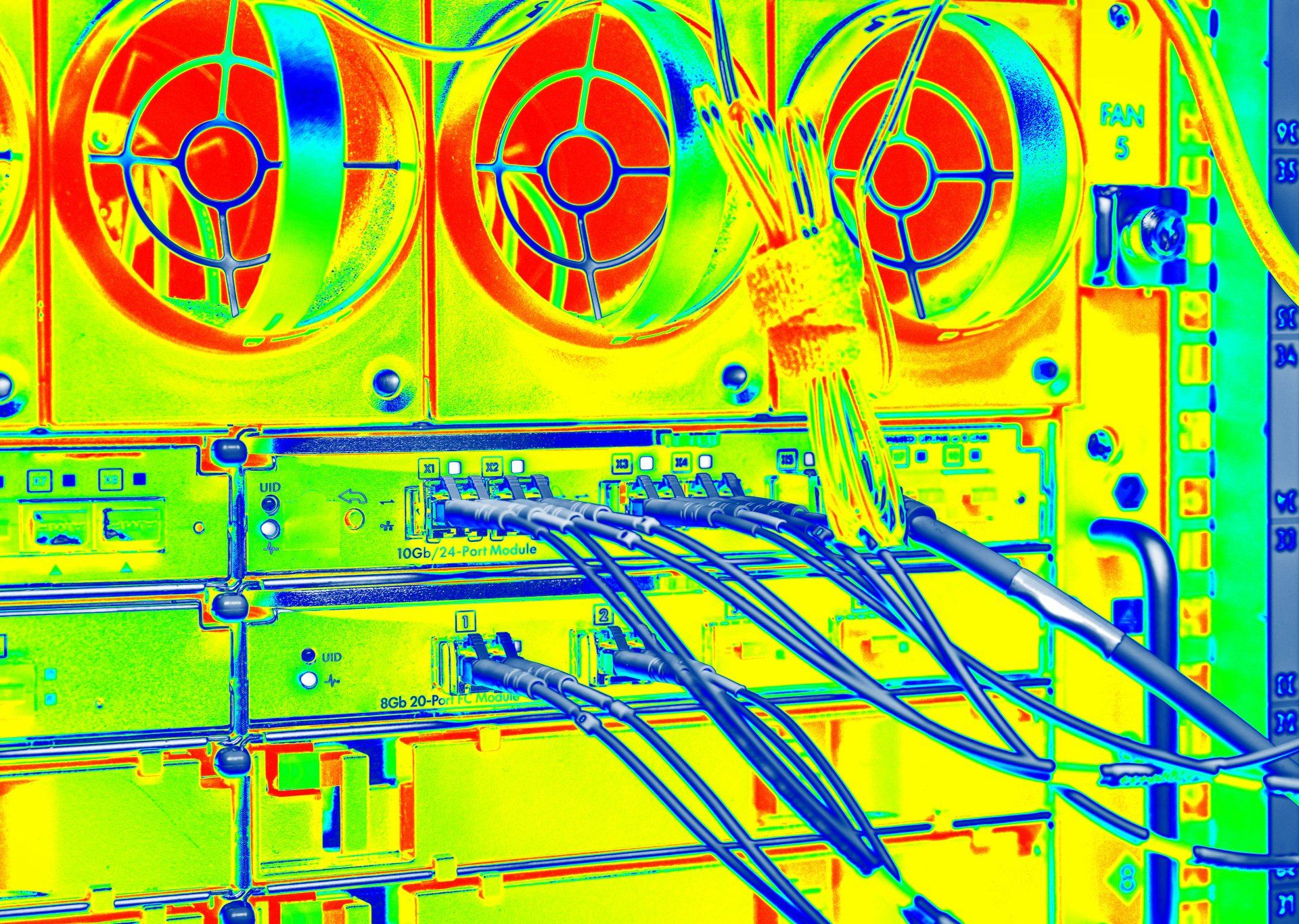

c) During this maintenance cycle, it was also noted that these high heat CPUs were accompanied by a high heat CT. The CT on the A feed to the 50 amp breaker is showing unexplained heat. It is not known why the CT is getting hot or how this relates to the high heat on the CPU. It should be noted that the wire feeding the power indicator light discussed above is attached to the same breaker that is creating the high heat CT. Example images for the three issues noted above are included below

2. Excessive heat on one or more wires from the Buss Rail. Two devices showed this exception. On previous maintenance cycles, it was determined that the cause of this issue was a poor solder joint inside the stab to the Buss Rail. At a minimum, these Buss Plugs should be thermally imaged again during the next maintenance cycle to confirm the readings and check for any change.

3. Unexpected heat on a wire on the feed side of breaker 2. BP xxxx-xx-29 showed an unexpected higher heat on the feed to the second termination on breaker 2. This thermal signature indicates a possible poor termination of the wire to the breaker. At a minimum, this Buss Plug should be thermally imaged again during the next maintenance cycle to confirm the readings and check for any change.

1. Buss Plugs with 50 amp breakers – Three distinct issues were noted on these Buss Plugs:

a) Excessive heat coming from a wire feeding a power indicator light occurred on 28 devices. These lights are only used on the Buss Plugs with 3 phase 50 amp circuits. Every Buss Plug of this type showed this exception. Many of these wires are in excess of 90 degrees C (200 degrees F) which is above the rating for the insulation on the wire. The heat on this wire has the potential to cause the insulation to fail and leave a bare wire inside the Buss Plug creating a safety and potential down time hazard. If the indicator light is not needed, it is recommended that the power wire to the light be cut and capped during the next available maintenance period.

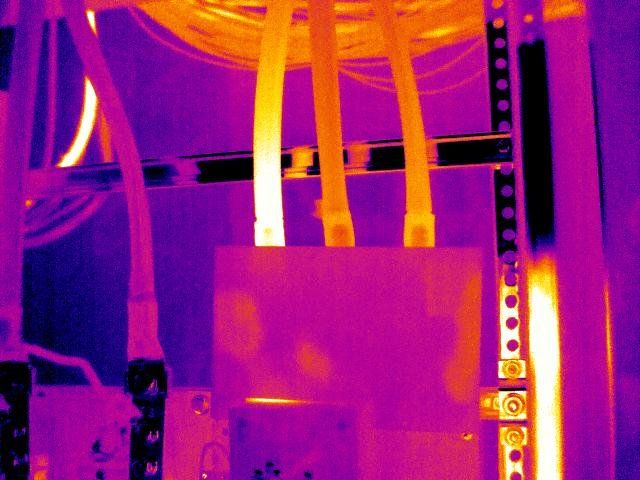

b) High heat on the monitoring system board CPU. Over the past year Panoptic Solutions has inspected more than 2,000 Buss Plugs and their accompanying monitoring systems. The temperatures recorded on the monitoring board CPU universally fall between 48 and 57 degrees C (120 and 135 degrees F.) In six Buss Plugs an abnormally high heat was recorded, some in excess of 64 degrees C (147 degrees F.)

c) During this maintenance cycle, it was also noted that these high heat CPUs were accompanied by a high heat CT. The CT on the A feed to the 50 amp breaker is showing unexplained heat. It is not known why the CT is getting hot or how this relates to the high heat on the CPU. It should be noted that the wire feeding the power indicator light discussed above is attached to the same breaker that is creating the high heat CT. Example images for the three issues noted above are included below

2. Excessive heat on one or more wires from the Buss Rail. Two devices showed this exception. On previous maintenance cycles, it was determined that the cause of this issue was a poor solder joint inside the stab to the Buss Rail. At a minimum, these Buss Plugs should be thermally imaged again during the next maintenance cycle to confirm the readings and check for any change.

3. Unexpected heat on a wire on the feed side of breaker 2. BP xxxx-xx-29 showed an unexpected higher heat on the feed to the second termination on breaker 2. This thermal signature indicates a possible poor termination of the wire to the breaker. At a minimum, this Buss Plug should be thermally imaged again during the next maintenance cycle to confirm the readings and check for any change.

Example Images:

The following are example images of the 50 amp breaker issues discussed above:

BP xxxx-xx-38 showing high heat on CT and wire feeding power indicator light.

BP xxxx-xx-38 showing high heat on the monitoring board CPU.

951 7th Street, Stu G

- Rochelle, IL 61068

Optimize your maintenance cycles

Save Money - Avoid Downtime